Hebei Jingzheng Pump Industry Co., LTD

Factory Supply

There are no middlemen taking a cut

Years Of Experience

Have many years of export experience

Support Customization

Process as per customer requirements

Fast Delivery

Large inventory and prompt delivery

ABOUT JINGZHENG

Focus On The R&D Of Brake Drums And Wheels

A globally trusted manufacturer and supplier of water pumps

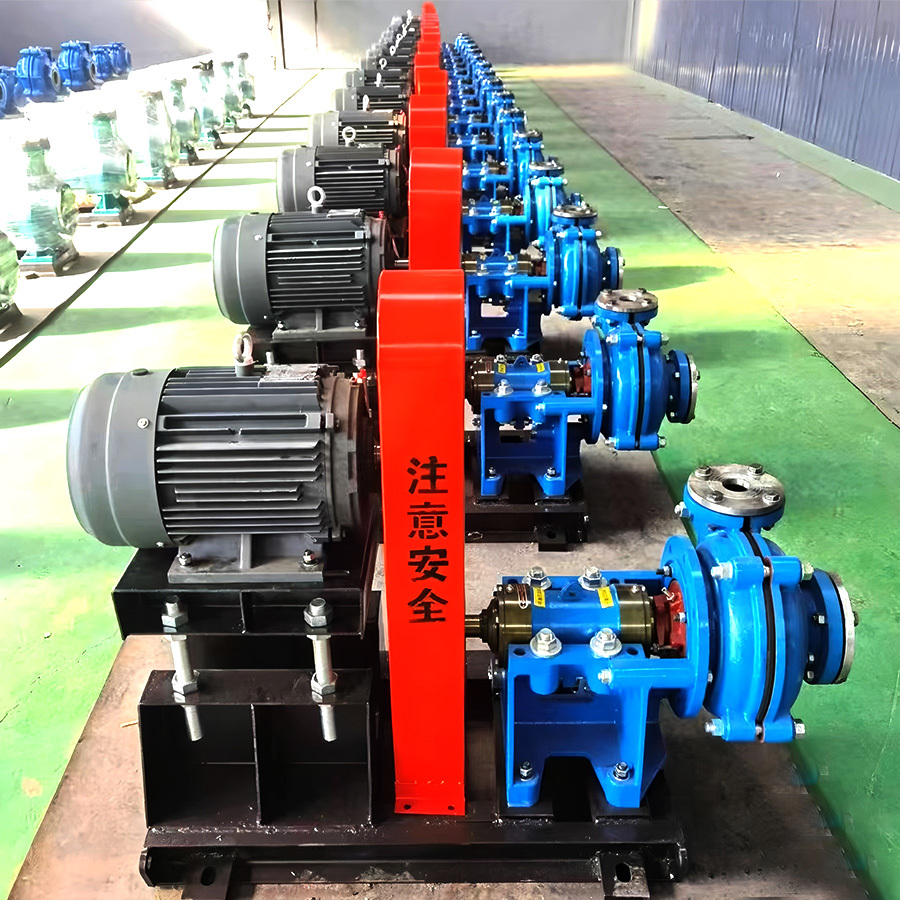

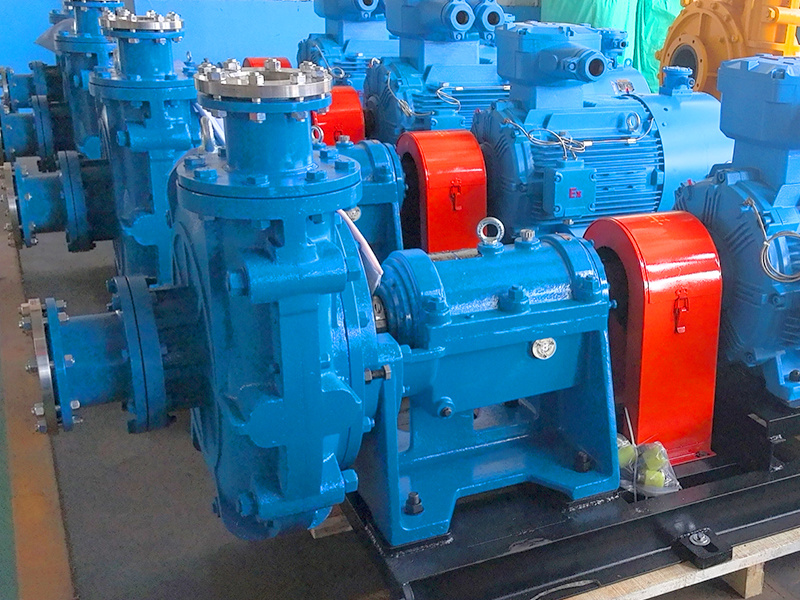

A company engaged in the production and processing of slurry pumps, mud pumps, mixed flow pumps and other products

WHO WE ARE

With

Hebei Jingzheng Pump Industry Co., Ltd. is a company specializing in the production and processing of slurry pumps, mud pumps, mixed flow pumps and other products, and has a complete and scientific quality management system. The integrity, strength and product quality of Hebei Jingzheng Pump Industry Co., Ltd. have been recognized by the industry. Welcome friends from all walks of life to visit, guide and conduct business negotiations.

Customization

Meet all your needs, no matter the size, even if you only have ideas, we will help you to achieve. We have a strong R&D technology team that can develop and produce products based on the drawings or samples provided by customers.

Industry Experience

Cooperative Clients

Sales country and region

Quality Assurance Has Always Been Our Top Priority

Equipped with a complete production line and a scientific quality management system, every link is strictly controlled to ensure the stable and reliable quality of the products.

Strong production capacity

As an original manufacturer, we have a large factory to ensure rapid production of various styles. We can efficiently complete orders ranging from small to large quantities, and replenish goods promptly.

Customized service professional

Supports OEM/ODM processing, can be developed and produced according to requirements, meet personalized customization, and can also be adapted to distribution and consignment.

The after-sales system is perfect

We offer quick quotations before sales, follow up on production during sales, and provide considerate services such as installation and maintenance after sales. The quality guarantee is guaranteed.

One-Stop Customized Solutions

Consultation and communication

Communicate by phone and email to clarify the supply requirements

Sign Cooperation

If there are no documents, we can provide the design; if there are documents, we can directly produce it

Design proofing

Sign a cooperation agreement and make a partial advance payment

Arrange production

Confirm the order, conduct research and development, production, and quality inspection

Delivery and receipt

Send out quickly and settle the payment in full

After-sales consultation

Follow up on the after-sales usage situation

Do you have questions?

For a fast response, fill in the form and our team will get back to you shortly.

News & Media

Our team is constantly working to meet the demands and requests of our customers. If you prefer us in your projects, we will be happy to work with you.