Hebei Jingzheng Pump Industry Co., LTD

Contact

E-mail :

jingzheng@cnjzpump.com

Phone/WhatsApp:

+86 13483266789

Address:

Lujing Village, Shifo Town, Anguo City, Baoding City, Hebei Province, China

PRODUCTS

3-inch and 4-inch slurry pump with a 7.5 kW motor, delivering a flow rate of 80–100 cubic meters per hour and a head of 16–20 meters (capable of horizontal输送 over 150–200 meters).

High-chromium wear-resistant alloy: Suitable for severe abrasive conditions such as mining and metallurgy.

4-inch silt pump + 15kW motor, with a flow rate of 120–150 cubic meters and a head of 16–20 meters. (Can convey material over distances of 200–300 meters horizontally.)

The SWQ and SWBQ series submersible sewage pumps boast remarkable energy-saving performance, anti-entanglement features, non-clogging capabilities, as well as automatic installation and automatic control. They also deliver exceptional efficiency in handling solid particles and long-fiber waste.

Metal body: Crafted from thickened material for long-lasting durability and guaranteed quality.

Slurry pump impeller and pump casing guard plate

Slurry pump impeller, submersible slurry pump component, high-chromium alloy impeller, pump casing, volute, and flow-through parts

S SH Double-Suction Centrifugal Pump

The pump's internal cavity features a grooved design, with water channels on both sides capable of storing the large volume of water drawn in by the suction port, which is then forced into the central impeller's discharge water channel—delivering high flow rates and significant head.

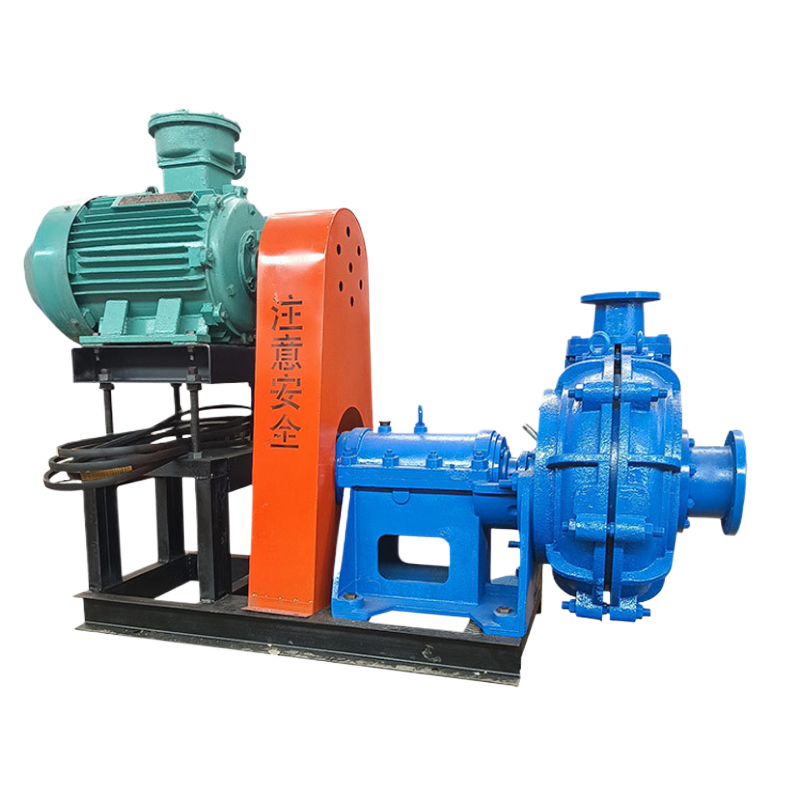

ZJ Variable-Speed Transmission Slurry Pump

High-chromium wear-resistant alloy: Suitable for severe abrasive conditions such as mining and metallurgy.

YZ Submersible Slurry Pump Assembly

Slurry pump impeller, high-chromium alloy impeller, pump casing, and volute—flow-through components

Made with thickened material, ensuring long-lasting quality and durability.

Slurry pump impeller components

Slurry pump impeller, submersible slurry pump component, high-chromium alloy impeller, pump casing, volute, and flow-through parts

3-inch and 4-inch slurry pump + 7.5 kW motor, with a flow rate of 80–100 cubic meters and a head of 16–20 meters (capable of conveying material over a distance of 150–200 meters in a flat layout).

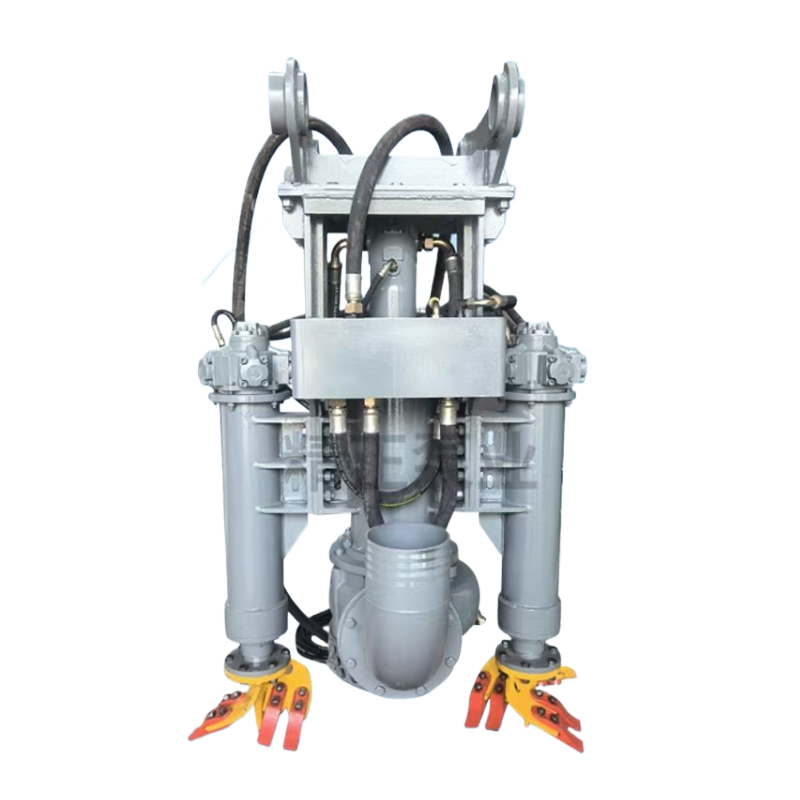

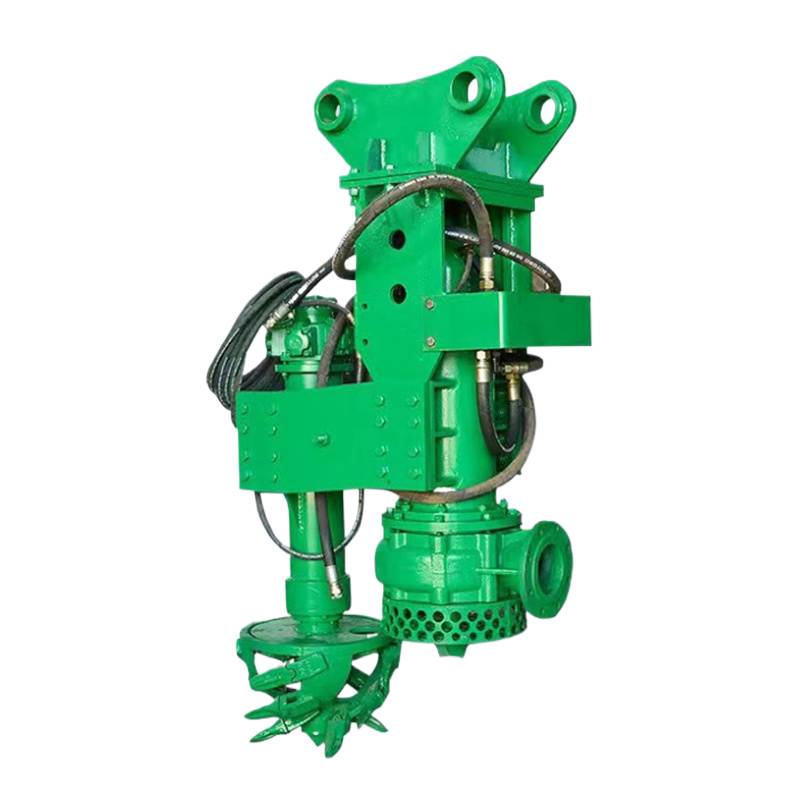

Excavator dredging pump, excavator sand and mud pump, hydraulic slurry pump, sand and mud transfer pump, Komatsu Model 300-7 excavator pump

ZJQ Submersible Sand Suction Pump

It can be widely used in various applications, including metallurgical ore dressing, tailings transportation, hydraulic ash removal in power plants, coal washing and beneficiation, as well as urban sewage discharge.

Made with thickened material, ensuring long-lasting quality and durability.

YSQ Excavator-Dedicated Mortar Pump, ZJQ Submersible Hydraulic Slurry Pump, Dredging Mud Pump, Silt & Sand Bottom-of-River Sand Extraction Pump

Stirring wheel design enhances efficiency

Ensures stable operation

Stirring wheel design enhances efficiency.

Ensures stable operation.

A widened and thickened base at the bottom reduces vibrations and extends usage time.

Double-suction pump water pump, centrifugal pipeline sewage pump, 380V three-phase industrial high-flow agricultural irrigation submersible

Powerful performance: Slurry pump—high head/large flow rate/large diameter

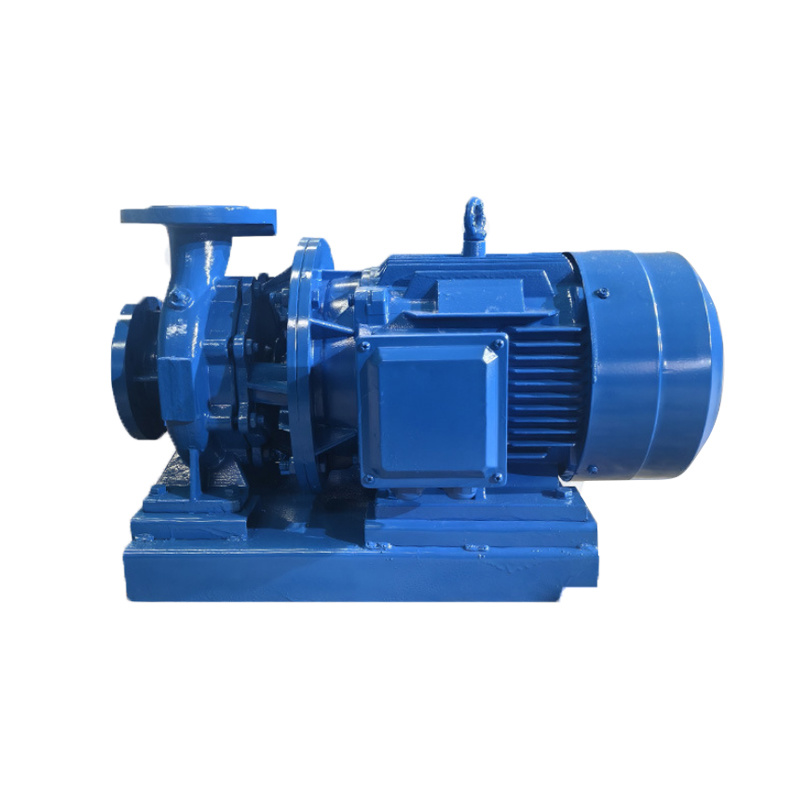

Single-stage, single-suction pipeline pump

Single-stage, single-suction pipeline pump with a pure copper motor—powerful and durable, ensuring reliable performance without overheating or damage during operation.

The pump's internal cavity features a grooved design, with water channels on both sides capable of storing the large volume of water drawn in by the suction port—this water is then forcefully pushed into the central impeller’s discharge channel, delivering high flow rates and significant head.

Precision-cast pump body: Crafted from thickened material for long-lasting durability and guaranteed quality.

Metal body: Crafted from thickened material for long-lasting durability

Quality assurance

A hydraulic sand pump is a sediment-extraction device powered by a hydraulic system, primarily used in projects such as river dredging, mineral sand pumping, seabed dredging, and construction of building foundations.

Metal body: Crafted from thickened material for long-lasting durability

Quality assurance

High-chromium alloy: Made with thickened material for long-lasting durability and guaranteed quality.

3-inch and 4-inch slurry pump + 7.5 kW motor, with a flow rate of 80–100 cubic meters and a head of 16–20 meters (capable of conveying material over a distance of 150–200 meters in a flat layout).

IS Clearwater Centrifugal Pump

Metal body: Crafted from thickened material for long-lasting durability and guaranteed quality.

Made with thickened material, ensuring long-lasting quality and durability.

It can be widely used in various applications, including metallurgical ore dressing, tailings transportation, hydraulic ash removal in power plants, coal washing and beneficiation, as well as urban sewage discharge.

A hydraulic sand pump is a sediment extraction device powered by a hydraulic system, primarily used in projects such as river dredging, mineral sand pumping, seabed excavation, and construction foundation work.

Metal body: Crafted from thickened material, ensuring long-lasting quality and durability.

The SWQ and SWBQ series submersible sewage pumps feature remarkable energy-saving performance, anti-entanglement capabilities, non-clogging design, automatic installation, and advanced automatic control—making them uniquely effective in handling the discharge of solid particles and long-fiber waste.

4-inch silt pump + 15kW motor, with a flow rate of 120–150 cubic meters and a head of 16–20 meters. (Can convey material over distances of 200–300 meters horizontally.)

Hydraulic Sediment Pump

Capacity: 180-360m³/h

Speed: 1480 r/min

Power: 110-160kw